Sienza Energy has recently unveiled a press release showcasing how its unique and proprietary 3D nanostructured pure silicon anode addresses safety concerns in the global electric vehicle (EV) market.

The release follows two high-profile battery fire incidents in South Korea. A fire at the Aricell battery plant resulted in 22 fatalities, and another incident saw a Mercedes EQE fire in a parking lot, causing damage to over 140 vehicles, hospitalizing 23 people, and forcing the emergency evacuation of more than 700 residents.

Dr. Azin Fahimi, Chief Technology Officer at Sienza Energy, stated that the company's 3D nanostructures improve heat dissipation, preventing localized hotspots and reducing the risk of thermal runaway, making Sienza's batteries safer and more reliable in operation.

Dr. Matthew Tasooji, CEO of Sienza Energy, also noted that Sienza's batteries enhanced mechanical stability can better absorb and distribute mechanical stress, thereby reducing the likelihood of internal short circuits.

According to research by KBB, the record of hybrid and fully electric vehicles in terms of fire incidents is significantly lower than that of gasoline-powered vehicles. Lithium-ion EV batteries are meticulously engineered to mitigate the risk of thermal runaway, also known as fires. Despite this, EV fires, though relatively rare, attract significant attention and concern compared to gasoline-powered vehicles.

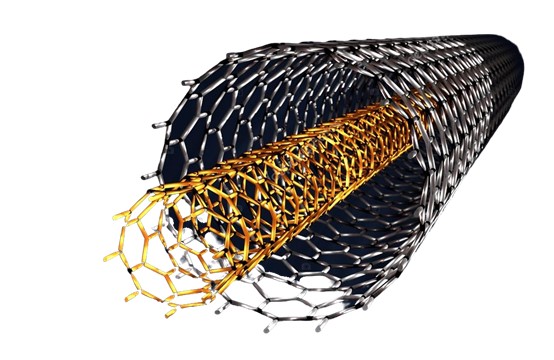

Sienza's website further explains that while traditional lithium-ion batteries deploy millions of micron-sized particles of active materials compressed and bound together with polymers to form an electrode, Sienza's batteries scale up to billions of 3D nanostructures, resulting in a surface area 100 times that of conventional batteries for chemical reactions. This expanded surface area, along with more efficient heat dissipation, is a key factor in the improved performance of the new battery.

The 3D nano silicon material is reported to have an energy density of 2,000Wh/L, with applications in EV power batteries reaching approximately 1,700Wh/L. Citing data from independent third-party validator Mobile Power Solutions, Sienza's founder Mory Gharib stated last March said "Sienza's 3D pure silicon anode has demonstrated an average energy density of 2,941 mAh/g." This significantly surpasses the 372 mAh/g of graphite anodes.

Sienza also emphasizes the outstanding performance of its silicon EV batteries, stating that it can be adapted for a wide range of uses, including aerospace and defense. In the field of electric vehicles, its EV battery is 46% smaller in volume than conventional lithium-ion batteries with the same cruising range. Correspondingly, compared to other batteries of equal volume, its EV battery range increases by 60%. The company also stated that, calculated based on a 46% volume reduction, its battery cells cost 48% less to manufacture than conventional cells. This promises to provide electric vehicle manufacturers with a smaller, lighter, and less costy EV battery.

Furthermore, the absence of cobalt and the company's adoption of a solvent-free dry manufacturing process that does not rely on N-methylpyrrolidone (NMP) and other additives make the batteries more environmentally friendly while reducing costs.

Headquartered in Pasadena, California, Sienza Energy is a battery technology startup incubated by Caltech and supported by Los Angeles philanthropist Patrick Soon-Shiong.

Earlier this year, Sienza Energy joined the Dutch Battery Competence Cluster (BCC-NL), aiming to explore the optimization of Sienza's battery architecture with Spatial Atomic Layer Deposition technology by joining the Dutch battery ecosystem for advanced battery manufacturing. SALD B.V., a Dutch company, has developed Spatial Atomic Layer Deposition technology, a patented process applicable on an industrial scale for coatings as thin as a single atom. The company states that these atomic nano-coating processes have the potential to revolutionize the entire industry, including battery production for automotive and smart devices.

Additionally, at the end of 2023, Azin Fahimi, Chief Scientific Officer of Sienza Energy U.S., led a team to cooperate with the American silicon anode company Sila Nanotechnologies. They are working together to implement different silicon anode materials to address the issues of expansion and "mechanical stress and eventual degradation of the anode material" in the application of silicon-based materials in lithium-ion batteries.