Recently, U.S. silicon anode material company Paraclete Energy announced that its new silicon anode material, SILO Silicon™, costs $35 per kilowatt-hour. The company plans to use SILO Silicon™ as a substitute for conventional graphite anodes commonly used in lithium iron phosphate (LFP) batteries.

The company stated that the current cost of LFP batteries is $53 per kilowatt-hour, and the adoption of SILO Silicon anodes will achieve further cost reduction, thanks to Paraclete Energy's advanced material science and optimized manufacturing processes. According to the company, Paraclete's SILO Silicon anode currently offers an energy density exceeding 520 Wh/kg, "significantly exceeding the capabilities of traditional graphite anodes".

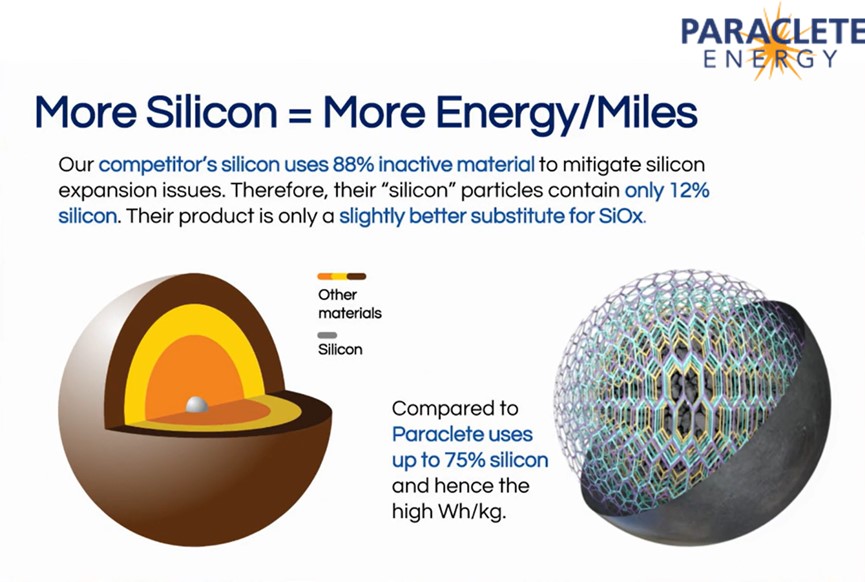

Paraclete launched its silicon anode material in the U.S. market just last month, announcing plans to release the product in the fourth quarter of this year. At that time, Paraclete also made some bold statements about its technological breakthroughs, claiming significant advantages over competitors: "Its unique polymer matrix architecture enables an industry-leading silicon concentration, providing up to 300% of the energy density of traditional graphite anodes, and performance more than 200% higher than competitors' silicon anode technologies. Moreover, in terms of pricing, this material allows for costs that are '33% cheaper per kilowatt-hour than traditional carbon-based products.'"

Jeff Norris, CEO of Paraclete Energy, stated that SILO Silicon™ will be a game-changer for the electric vehicle industry, "This technology directly addresses the market's critical needs, offering longer range, faster charging, and lower costs."

According to previous insights from the cleantX-Energy Research, earlier this year, the Argonne National Laboratory's research on Paraclete's SM-Silicon/3590™ nano-silicon product showed that Paraclete Energy's silicon anode material can increase the battery charging rate from 1C to 8C and improve capacity retention. This self-healing, highly conductive, porous cross-linked elastic nano-silicon material with up to 75% silicon content is key to achieving such high performance, far exceeding the ordinary silicon content of 12% in nano-silicon materials.