Great Power showcased its new energy storage batteries and solid-state battery technology at the product technology conference on August 28, 2024.

Focusing on three core areas—residential energy storage, grid energy storage, and solid-state battery technologies—Great Power introduced safer, more efficient, and more sustainable battery solutions to the market. In the field of energy storage, the company launched the POLAR series of residential energy storage cells for low-temperature applications and the high-power, high-capacity Fengpeng (Flying Power) cells with a capacity of 590Ah; in terms of new battery technology, the first generation of solid-state battery technology and future research and development directions were announced.

1. Low-Temperature Residential Energy Storage Cells POLAR: Focusing on Lithium-ion Battery Applications in Extreme Cold Regions

At this conference, addressing the concern about low-temperature anxiety, Great Power introduced the new generation of low-temperature residential energy storage batteries: the POLAR series, capable of charging in a wide temperature range from -30°C to 90°C.

Great Power has further broken through the low-temperature charging technology bottleneck through three core technologies: LTSC low-temperature superconductivity technology, micron-level adaptive structure, and multidimensional copolymer adhesive network. The charging temperature has been lowered to -30°C, with a charging and discharging efficiency of over 95% and stable performance at low temperatures, greatly satisfying the needs of customers in low-temperature residential energy storage. At the same time, the POLAR series, while ensuring the ultimate low-temperature application conditions of the cells, restores the high-temperature usage boundary of the cells through the material system composite platform, achieving the highest charging temperature of 60°C, spanning a 90°C charging temperature range, and meeting the needs of various complex and diverse end applications.

In terms of cycle life, Great Power has continuously optimized the cycle performance by constructing a high-dimensional stability and low-resistance cell interface with self-healing biomimetic SEI film technology. The POLAR series has achieved a cycle life of over 5000 cycles at 1C/1C, allowing users to use it for 15 years.

In terms of safety, considering the high safety requirements for home energy storage, the POLAR series can perfectly pass strict safety regulations such as thermal runaway tests. During the thermal runaway test, the POLAR series will not catch fire or explode within the stationary time after the voltage mutation triggered by thermal runaway.

Currently, the low-temperature residential energy storage cells of the POLAR series with capacities of 50Ah, 72Ah, and 100Ah have been mass-produced and delivered. The diverse capacity solutions of the POLAR series better meet the needs of customers for multi-scenario applications.

2. Fengpeng 590Ah Cell: High Energy Efficiency, High Cycle, High Power, High Safety Energy Storage Cells

Based on market demand, Great Power launched the new generation of large-capacity Fengpeng cells with a capacity of 590Ah, achieving 97% high energy efficiency, 10,000 cycles, and 2P high power, focusing on high safety, high power, and high energy efficiency.

Great Power has innovated in multiple dimensions, including material micro-nano structure design, three-dimensional superconductivity network construction, efficient lithium ion liquid phase transfer, and ultra-fast ion conductor interface repair, building an industry-leading ionic sponge high energy efficiency platform technology, and raising the energy efficiency level of Fengpeng 590Ah cells to 97%.

In terms of cycle life, based on the ten-thousand cycle platform technology, Great Power has achieved material system innovation that exceeds the cycle life of traditional lithium iron phosphate cells. The cycle life of Fengpeng 590Ah cells reaches over 10,000 times, greatly reducing the customer's total life cycle investment cost.

On the basis of the excellent energy efficiency and cycle performance of Fengpeng 590Ah cells, 2P ultra-high power has been achieved, fully meeting the end market's matching conditions for half an hour of use, and adapting to the energy storage frequency modulation requirements.

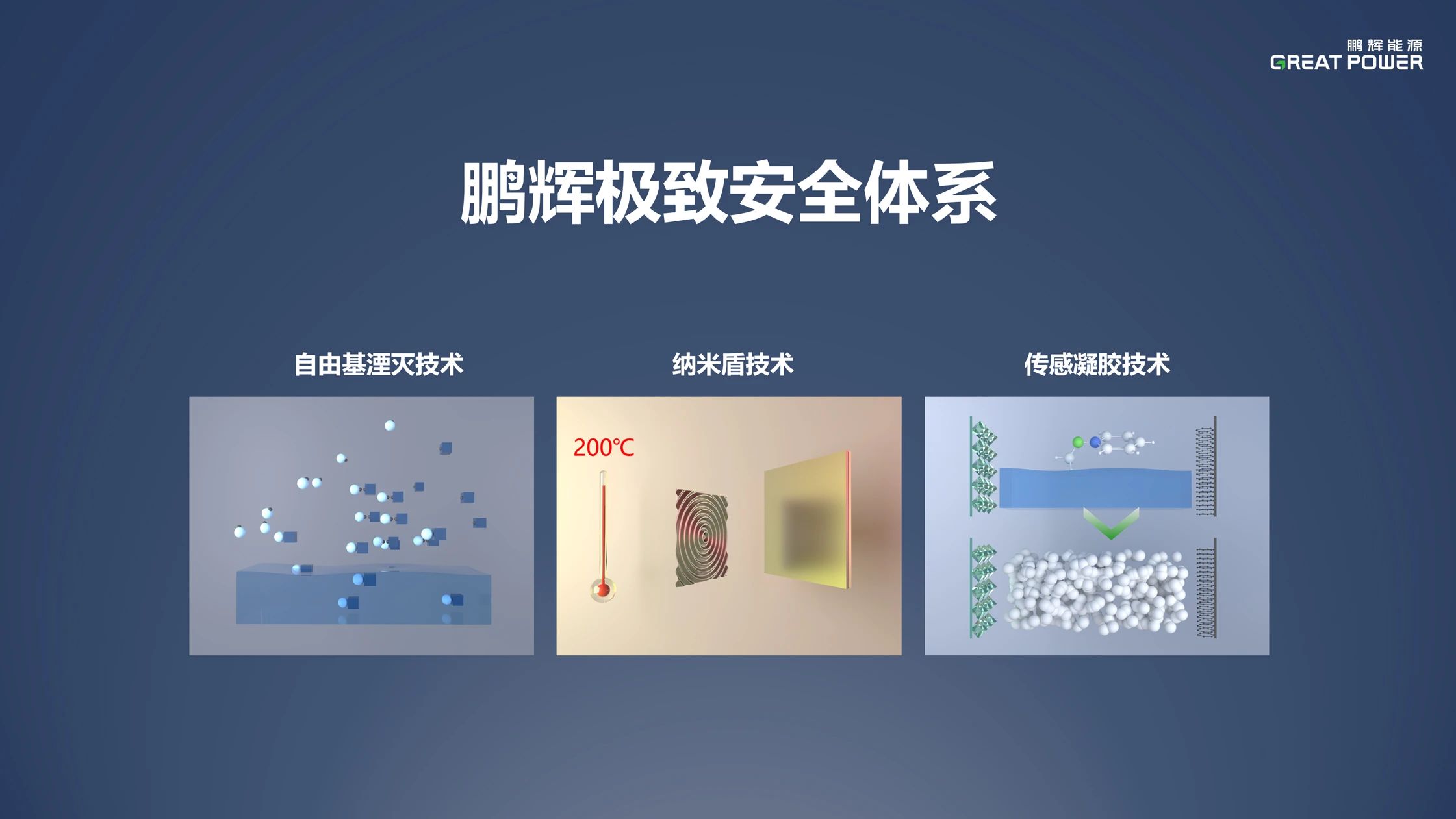

In terms of safety, Great Power has developed an ultimate safety system, quickly eliminating accumulated heat through free radical annihilation technology, and establishing a safe and reliable nano high-temperature resistant coating through nano shield technology. In terms of electrolyte, the sensing gel technology can realize the solid-liquid of high polymer, making the electrolyte gelatinous. Great Power has built a strong safety defense line for Fengpeng 590Ah cells from the underlying logic.

Fengpeng 590Ah cells are expected to be officially mass-produced in the fourth quarter of 2025.

3. The first generation of all-solid-state batteries: passing needle piercing and significantly reducing costs

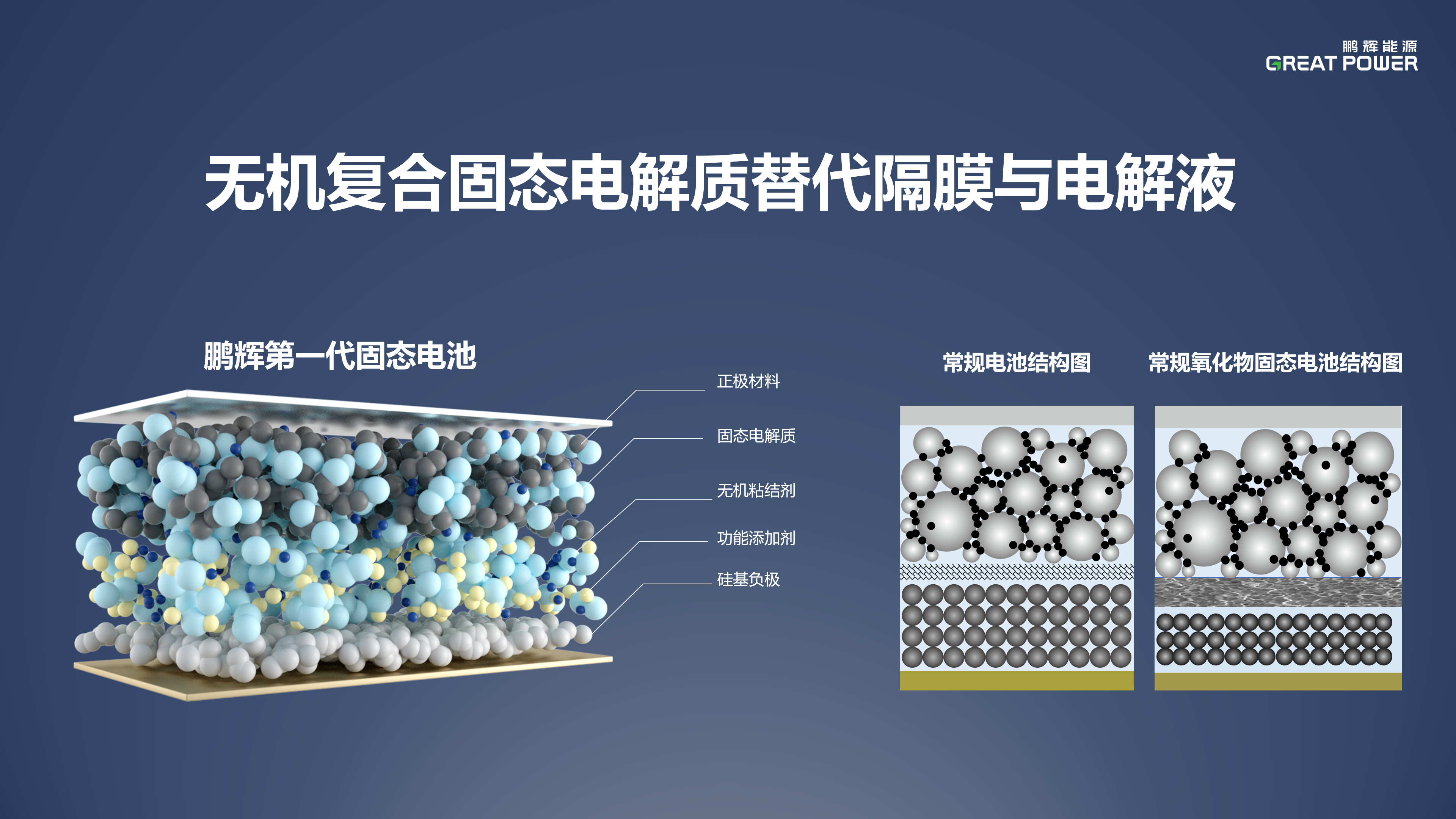

At this conference, Great Power also displayed the first generation of solid-state batteries with 20Ah physical and cross-sectional views. The company's self-developed high ionic conductivity, high stability, and low-cost oxide composite solid-state electrolyte has achieved a dual breakthrough in process and materials for solid-state batteries, solving the process technology problems of oxide solid-state electrolytes.

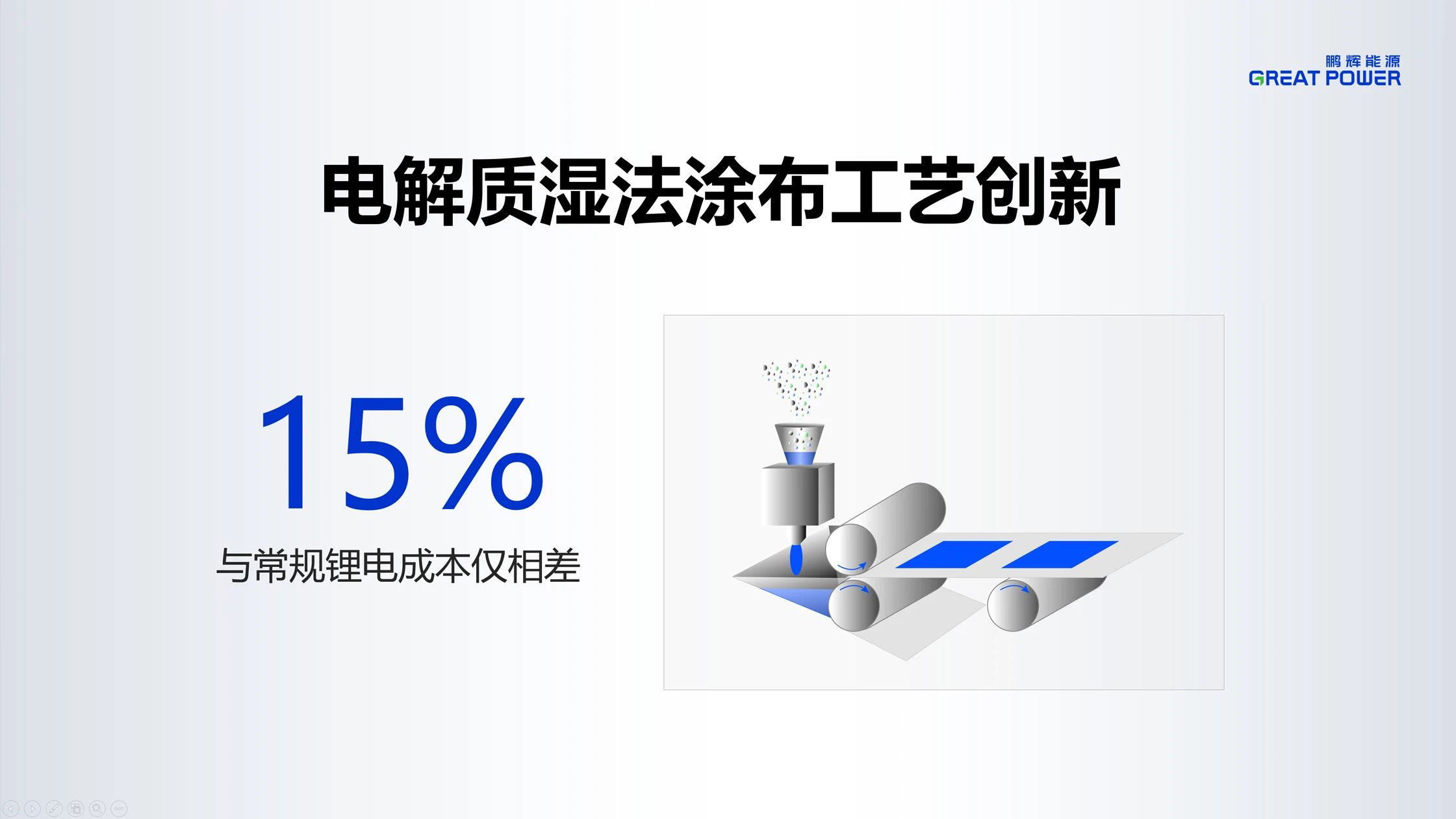

According to the news released by Great Power, the first generation of solid-state battery technology of Great Power, through the innovation of the wet coating process of the electrolyte, has solved the preparation process problem of the oxide electrolyte, greatly promoting the industrialization process of solid-state batteries of the Company. Traditional oxide electrolytes require high-temperature sintering to form dense ceramics, which is energy-intensive and inefficient. At the same time, the inherent brittleness of ceramics also makes it difficult to prepare large-capacity cells.

Through the unique wet coating process of the electrolyte, Great Power successfully bypassed the high-temperature sintering process of the oxide solid-state electrolyte, avoiding the inherent brittleness of ceramic materials, and greatly simplified the process. Solid-state batteries using this process are expected to be only about 15% more expensive than conventional lithium-ion batteries in overall cost. In the next 3-5 years, with continuous process optimization and further cost reduction of materials, it is expected to reach the same cost as conventional lithium-ion batteries.

The first-generation solid-state batteries of Great Power completely replace the separator and electrolyte with inorganic solid-state electrolytes, eliminating the safety hazards of organic electrolytes, bringing more possibilities for the development of the next generation of high-performance solid-state batteries. In addition, through a new type of inorganic composite binder, Great Power effectively improved the brittleness of ceramics, enhancing the adhesion and plasticity of the electrolyte layer, and greatly reducing the probability of internal short circuits in solid-state batteries. At the same time, functional additives are used to effectively improve the ionic conductivity of the inorganic composite electrolyte layer and reduce the internal resistance of the cell. By adding high thermal conductivity functional additives and safety additives, the thermal dissipation ability and safety performance of solid-state batteries are further enhanced.

In terms of safety, thanks to the self-developed composite solid-state electrolyte, high thermal conductivity additives, and automatic safety mechanisms, the first generation of solid-state batteries of Great Power can pass the most stringent nail puncture test. When subjected to nail puncture, it can quickly export and suppress the release of internal energy, effectively ensuring that the components of the solid-state batteries remain intact under extreme conditions, achieving no smoke, no fire, and no explosion, and avoiding danger from the source.

The first-generation solid-state batteries of Great Power also have excellent wide-temperature performance, which can be stably charged and discharged under -20°C to 85°C temperature conditions, achieving normal operation in extreme environments, suitable for various complex climates from extremely cold to hot.

The energy density of Great Power's first-generation solid-state batteries has reached 280Wh/kg. In 2025, the company will use a higher proportion of silicon-based anodes on the material side, and the energy density will reach more than 300Wh/kg. The company plans to start pilot R&D and small-scale production in 2025, and officially establish a production line and mass production in 2026.