The U.S. solid-state battery startup Factorial announced on September 10th the development of an all-solid-state battery, Solstice™, in collaboration with Mercedes-Benz. This battery utilizes dry battery cathode, achieving an energy density of up to 450Wh/kg, which can significantly extend the driving range of electric vehicles (EVs) and represents a more sustainable, energy-efficient, and cost-effective battery manufacturing process.

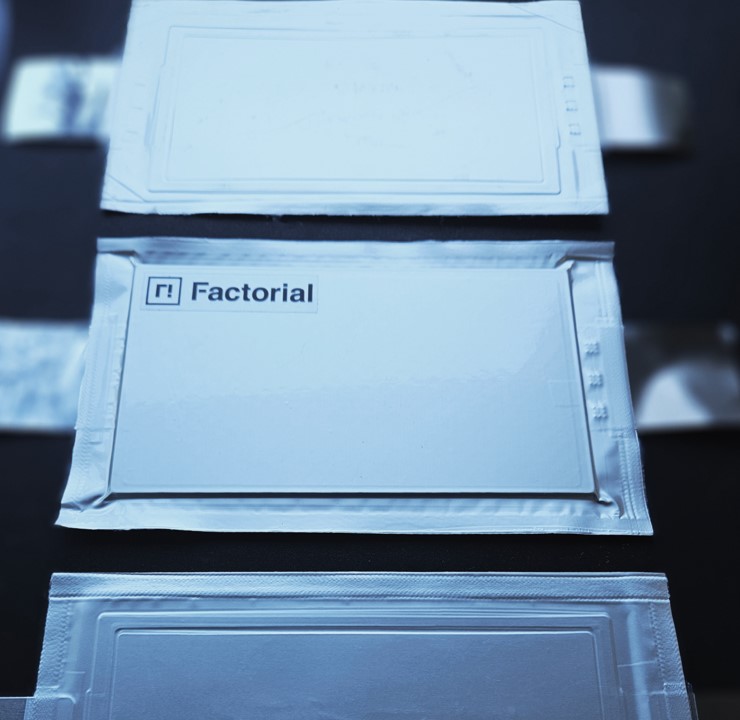

Factorial states that the Solstice™ battery, based on a sulfide solid-state electrolyte, complements their advanced FEST® (Factorial Electrolyte System Technology) and expands Factorial's solid-state battery technology from the EV power battery sector to the potential consumer electronics sector. Solstice™ is expected to be supplied to customers in the EV and consumer electronics industries before 2030.

Factorial's media release highlights that Solstice™'s high energy density can extend the range of electric vehicles by up to 80%, significantly reduce vehicle weight, and enhance vehicle efficiency. Its sulfide-based all-solid-state electrolyte addresses safety concerns related to the design of flammable and volatile liquid electrolytes, aiming to achieve an EUCAR safety level 2 and remain stable at operating temperatures above 90°C. This will also reduce the cooling system requirements within the battery pack, thereby lowering the overall cost of the vehicle.

Notably, Solstice™ employs a dry coating process in electrode manufacturing, eliminating harmful solvents and drying processes in traditional wet cathode production. Combined with these innovations, Solstice™ reduces operational costs, energy consumption, and environmental impact, contributing to a greener battery production future.

Markus Schäfer, Chief Technology Officer and Member of the Board of Management of Daimler AG and Mercedes-Benz AG, stated that the Solstice™ solid-state battery technology represents another milestone in the automotive group's collaboration with Factorial, helping the car manufacturer set new standards for electric vehicles in terms of range, cost, and performance.

In early June of this year, Factorial delivered B-samples of its solid-state batteries using its FEST® technology platform to Mercedes-Benz, marking the industry's first time a solid-state battery supplier provided B-samples to an EV manufacturer. The B-samples will be integrated into modules and battery packs, undergoing rigorous performance specification validation and battery pack design by Mercedes-Benz for extensive testing and optimization. Previously, Factorial provided Mercedes-Benz with over 1,000 100+Ah solid-state battery cells as A-samples for evaluation.

Mercedes-Benz signed a joint development agreement with Factorial in 2021 and led a $200 million round of investment in Factorial in 2022. To date, Factorial has established joint development agreements with global leading automotive manufacturers and battery chemical companies, including Mercedes-Benz, Stellantis, Hyundai Motor Company, Kia Corporation, and LG Chem.

The company has a research and development center and a 200MWh solid-state battery production line in the Greater Boston area of Massachusetts.