Lyten, an advanced materials and lithium-sulfur battery technology start-up headquartered in San Jose, California, announced on Tuesday (October 15) its plan to invest over $1 billion in the construction of the world's first lithium-sulfur battery gigafactory in Reno, Nevada.

The factory, which is planned to produce cathode active materials, lithium metal anodes, and both pouch and cylindrical lithium-sulfur battery cells, aims for a production capacity of 10GWh. The first phase of the factory is expected to come online in 2027, creating 200 jobs locally, with the potential to grow to over 1,000 jobs once the factory is fully operational. Financial support will come from investment institutions such as Stellantis, the parent company of Chrysler, and FedEx.

Reno, Nevada, is also home to Tesla's gigafactory, which produces battery packs and other components for its electric vehicles.

Since June 2023, Lyten has been manufacturing pouch and cylindrical lithium-sulfur batteries at its semi-automated factory in Silicon Valley, San Jose, California. The company claims that its lithium-sulfur batteries have a higher energy density and are 40% lighter than lithium-ion batteries of the same capacity. The startup has announced that it has a pipeline of hundreds of potential customers and expects its lithium-sulfur batteries to be used in drones, micromobility, space, and defense applications over the next two years.

Founded in 2015, Lyten, which focuses on lithium-sulfur batteries, 3D graphene materials, and sensor business, has received investments from companies such as Stellantis, FedEx, and Honeywell, and is one of the 44 "unicorn" companies in North America in 2023.

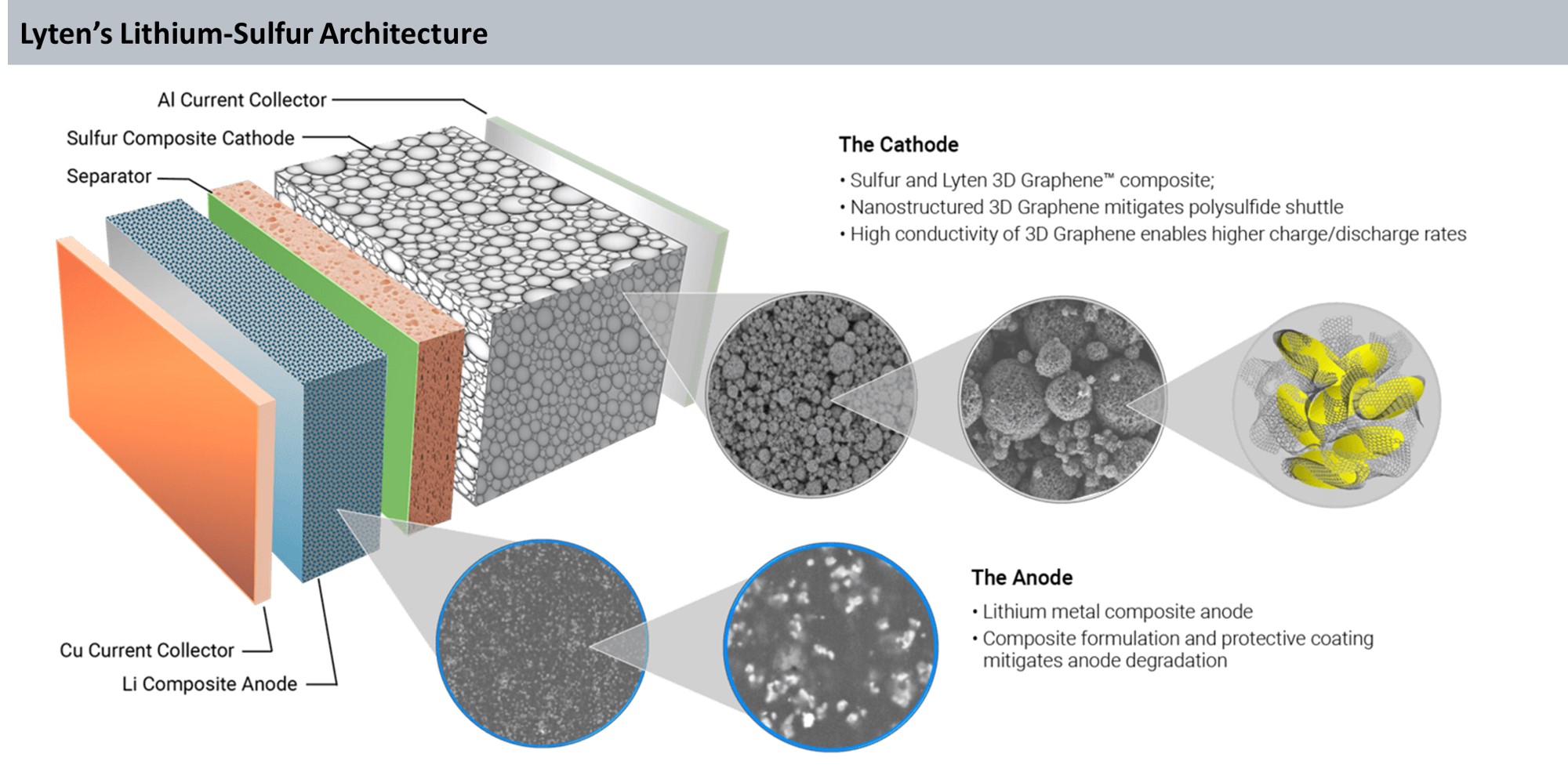

Lithium-sulfur batteries, which use abundant and low-cost sulfur, not only reduce dependence on key mineral resources such as nickel, manganese, cobalt, and graphite but also have the potential to provide one to two times the energy density of lithium-ion batteries. They have become one of the key routes for the European and American to develop next-generation batteries so as to reduce dependence on China's battery industry chain. Due to the difficulties in the lithium-sulfur battery material technology, business insiders previously expected that lithium-sulfur batteries would not be mass-produced until 2030. Lyten's plan for the mass production giga-factory indicates that the company has made certain technological breakthroughs in lithium-sulfur battery materials.

Since May 2023, Lyten has operated a semi-automated lithium-sulfur battery pilot line in San Jose, California, producing cathode active materials, lithium metal anodes, as well as pouch and cylindrical batteries. Lyten also plans to develop sulfur graphene composite cathode materials through its expertise in 3D graphene materials.

In January of this year, Lyten collaborated with Canadian lithium metal anode company Li-Metal to promote the sustainable production capacity of lithium metal and the development of special lithium ingots, helping to commercialize lithium-sulfur battery technology and claiming to establish a local North American supply chain for the next generation of batteries.

In February, Lyten received $4 million in funding from the US Department of Energy, and planned to collaborate with several US research institutions and lithium companies, including Stanford University and Arcadium Lithium (recently acquired by Rio Tinto), to accelerate the development and commercial production of high-capacity, long-life lithium-sulfur batteries.

In February of this year, Stellantis announced that its Chrysler Halcyon Concept, based on the STLA Large electric vehicle platform, plans to use Lyten's 800V high-voltage 3D graphene lithium-sulfur batteries. Stellantis Ventures, the venture capital fund of the automotive group, invested in Lyten in May 2023 to accelerate the commercial application of Lyten's 3D graphene batteries in the electric vehicle market.

In May 2024, Lyten announced that it had provided A-samples of its 6.5 Ah (C/3 discharge rate, 25C) lithium-sulfur pouch batteries to Stellantis and other US and EU automotive manufacturers for sample evaluation, laying the foundation for the next step in commercial applications.