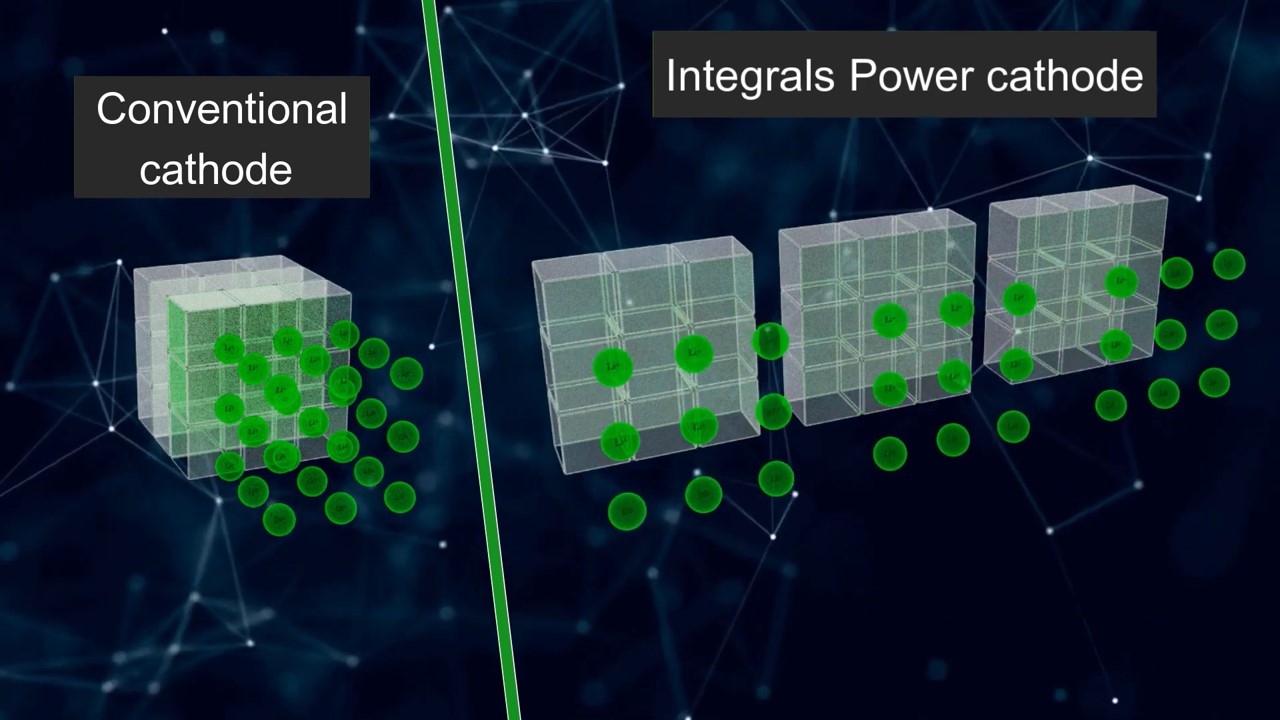

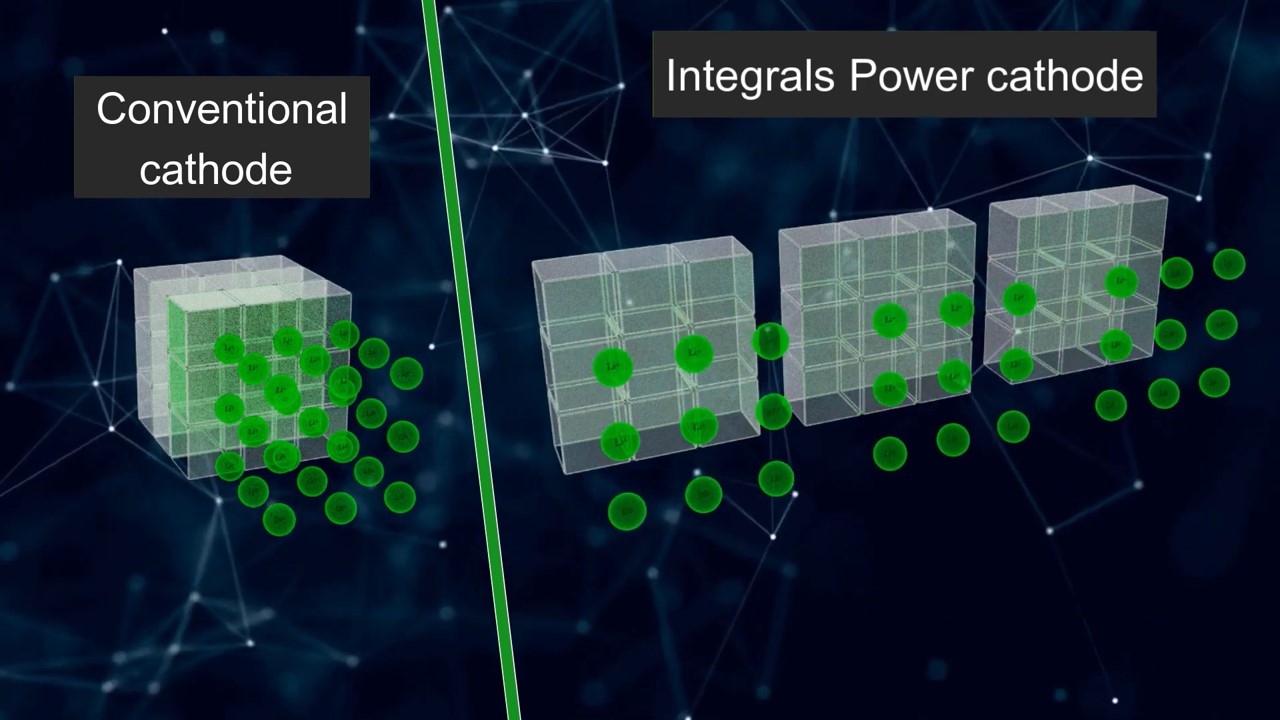

Integrals Power has recently announced a significant breakthrough in the development of Lithium Manganese Iron Phosphate (LMFP) cathode active materials, which could increase the range of electric vehicles by up to 20%. Leveraging its proprietary material technology and patented manufacturing process, the company has successfully overcome the typical decline in specific capacity associated with an increase in manganese content.

According to the company's release, while the manganese content in LMFP materials typically ranges from 50-70%, Integrals Power's LMFP materials boast a manganese content as high as 80%, with a higher specific capacity of 150mAh/g; the operating voltage also reaches 4.1V, higher than the 3.45V of LFP materials.

Third-party testing conducted by the Graphene Engineering Innovation Centre (GEIC) at the University of Manchester on coin cells based on the aforementioned LMFP battery materials has verified the performance. Testing is now underway on the company's LMFP pouch cells. Subsequently, Integrals Power will be sending samples to battery manufacturers and OEM clients for their evaluation and testing. Integrals Power is producing these high-performance LMFP cathode materials at its new UK facility, alongside its proprietary LFP materials.

Integrals Power Founder and CEO Behnam Hormozi stated that the challenge the automotive industry has long been trying to overcome is to increase the percentage of manganese in LMFP batteries to a higher level while maintaining the same specific capacity as LFP. Using traditional methods, the more manganese added, the more the specific capacity drops, meaning high manganese content cannot provide high energy density. "Our proprietary materials and patented production processes have enabled us to overcome this trade-off, increasing manganese content to 80%, placing us at the cutting edge of LMFP chemistry." He also mentioned that the battery cells produced using Integral Power's LMFP materials demonstrated competitive specific capacity during testing, highlighting the potential of this material to enhance electric vehicle efficiency and reduce costs by increasing range.

The UK is committed to establishing localized manufacturing to develop a sustainable battery industry, reducing dependence on global supply routes, and strengthening supply chain security, aiming to meet the country's goals of banning new internal combustion engine vehicles by 2030 and achieving net-zero emissions by 2050.