On October 28th, Australian media reported that lithium-sulfur battery startup Li-S Energy (ASX: LIS) has achieved an energy density close to 500Wh/kg with its lithium-sulfur batteries at its Phase 3 automated pouch cell production facility located in Geelong Victoria, Australia, reaching an industry-leading level. Following the announcement of a significant breakthrough in the field of lithium-sulfur battery chemistry, the company's stock price soared by 58%.

The company targets the rapidly growing markets of drones, defense, and electric aviation. For its existing partners and target customers, the higher energy density means lighter batteries, which further enhance potential range, payload, and operational/loitering time. This technological breakthrough may bring Li-S Energy one step closer to the commercial application of lithium-sulfur batteries.

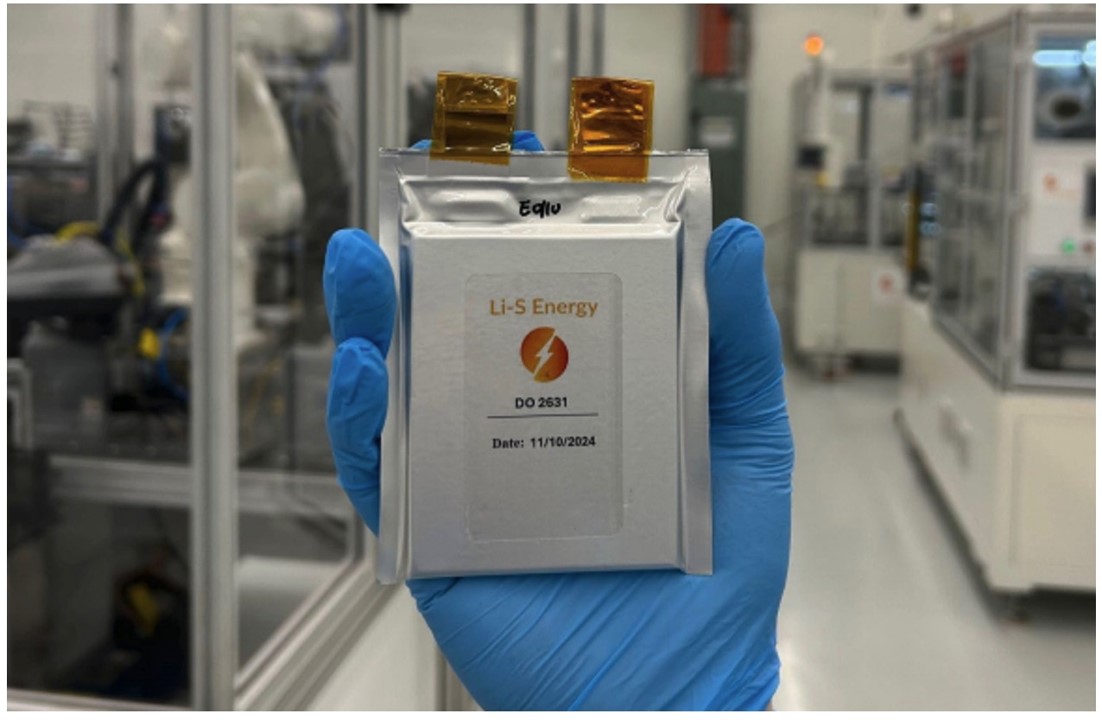

Through its Australian largest, 2MWh pouch cell production plant Phase 3 automated facility, Li-S has now manufactured full-size 10Ah semi-solid-state batteries that provide an energy density of 498Wh/kg on the first discharge and an industry-leading 456Wh/kg after formation cycling, with the cells continuing to cycle in ongoing testing.

Last month, the company delivered test cells to its first batch of key partners to validate the performance of aerospace battery packs integrating Li-S batteries and its newly developed intelligent battery management system (BMS).

Mark Xavier, CEO of Li-S partner V-TOL Aerospace, commented on the impact of this battery technology on the drone and aerospace industries, stating that the battery's performance exceeded their expectations and initial requirements for the joint development of the Pegasus unmanned air system. He anticipated that cell performance at this level would generate substantial global interest and opportunities for Li-S across the drone, aerospace, and defense sectors.

Li-S provided V-TOL Aerospace with the LIS GEN3 third-generation semi-solid-state battery technology announced in April 2023. The 10Ah lithium-sulfur battery achieving 456Wh/kg energy density is currently at the world's leading level in terms of technological breakthroughs. The company is currently producing 10Ah and 20Ah pouch cells on its test line, continuing to send samples to customers for testing and validation. At the same time, the company is working with current partners on BMS and battery pack design at the Geelong facility. "In the coming months, we expect to sign up more partners and assist them in integrating our cell and BMS technologies into their applications," they stated.

Li-S Energy expressed its commitment to enhancing Australia's sovereign manufacturing capabilities, reducing supply chain risks in battery technology, and providing high-value export opportunities.

On October 15th of this month, Lyten, a U.S. lithium-sulfur battery company invested in by Stellantis, announced plans to invest over $1 billion in constructing a 10GWh lithium-sulfur battery factory in Nevada, indicating that the company has also achieved certain technological breakthroughs in the field of lithium-sulfur batteries. The company had already provided A-samples of its 6.5 Ah (C/3 discharge rate, 25C) lithium-sulfur pouch batteries to Stellantis and other U.S. and EU automotive manufacturers in May for sample evaluation and plans to deliver samples to over 20 potential customers by the end of this year. Lyten aims to deliver commercially viable batteries to aerospace and defense customers this year.