Recently, the Franco-Italian automotive company Stellantis announced a joint development agreement with American lithium-sulfur battery technology company Zeta Energy to collaborate on the development of lithium-sulfur batteries and promote their application in the field of electric vehicles (EVs).

According to the announcement made by both parties, lithium-sulfur batteries offer a lighter weight battery pack at the same volume, enabling greater driving range, improved handling, and enhanced performance. The technology also has the potential to improve fast-charging capabilities by up to 50%. In terms of cost, lithium-sulfur batteries are expected to be less than half the price per kWh of current lithium-ion batteries.

“Our collaboration with Zeta Energy is another step in helping advance our electrification strategy as we work to deliver clean, safe and affordable vehicles,” said Ned Curic, Stellantis Chief Engineering and Technology Officer. “Groundbreaking battery technologies like lithium-sulfur can support Stellantis’ commitment to carbon neutrality by 2038 while ensuring our customers enjoy optimal range, performance and affordability.”

Compared to traditional lithium-ion batteries, lithium-sulfur battery technology provides higher performance at a lower cost. Sulfur is widely available and cost-effective, significantly reducing battery production costs and supply chain risks. Zeta Energy's lithium-sulfur battery technology utilizes waste materials, methane, and unrefined sulfur (a byproduct from various industries), and does not require the use of cobalt, graphite, manganese, or nickel, resulting in significantly lower CO2 emissions.

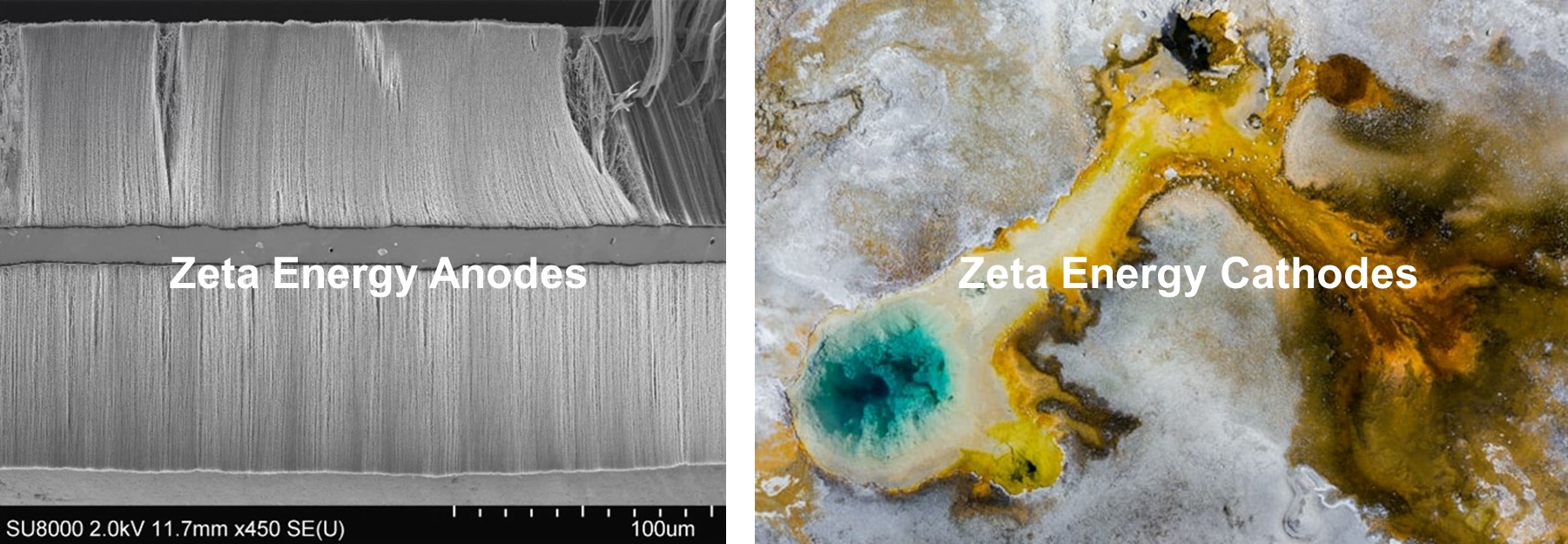

Zeta Energy's lithium-sulfur batteries feature 3D structured metallic anodes made of lithiated vertically-aligned carbon nanotubes, double-sided on copper foil, with high capacity and free from lithium dendrites. Zeta's cathode is based on a sulfurized carbon material, offering high stability and superior sulfur content, outperforming current metal-based cathode materials, and is free from cobalt, graphite, nickel, or other precious metals, making it cost-effective and reducing cost volatility and resource dependence.

Zeta Energy's lithium-sulfur batteries will be manufactured based on existing gigafactory technology, aiming to shorten the supply chain in Europe or North America and fully realize the localization of the power battery supply chain.

The collaboration includes pre-production development and planning for future production, with the goal that by 2030, the completed lithium-sulfur battery project will power Stellantis electric vehicles. Stellantis aims to launch 75 battery-electric vehicle models by 2030, according to its strategic plan “Dare Forward 2030”. Stellantis will employ dual-chemistry battery approaches and explore innovations in battery cell and pack technologies.

In terms of lithium-sulfur battery technology deployment, in addition to Zeta Energy, Stellantis has also provided financial support to another North American lithium-sulfur battery startup, Lyten. Lyten

announced in October that it will invest $1 billion to build the world's first lithium-sulfur battery gigafactory in Reno, Nevada, with a production capacity of 10GWh, and the first phase of the factory plans to start operation in 2027.