Please enter your registered phone number below to receive the verification code

BMW Group started its electrification strategy early, with the first prototype of the battery-electric MINI Cooper in 2008, and as of the end of this year's first quarter, BMW i3 has delivered a cumulative total of one million units. Recently, Kurt Vandputte and Peter Lamp, two battery experts from BMW Group, accepted a media interview at the BMW Group Battery Cell Competence Centre (BCCC).

BMW’s Battery Manufacturing Competence Center (CMCC) in Passdorf, Germany

Mr. Vandputte said that based on an in-depth understanding and expertise in battery technology and battery production, BMW has formulated a clear battery strategy. After all, this is indeed the core of the electric vehicle business. In response to the current challenges faced by manufacturers, as the automotive industry transforms, BMW also commits to providing customers with the "ultimate driving machine."

According to information previously released by BMW Group, the standardized sizes of BMW's sixth-generation cylindrical batteries are 4695 and 46120. Compared with the square batteries of the fifth-generation BMW batteries, the nickel content on the cathode side of the sixth-generation BMW cylindrical batteries has increased, while the cobalt content has been reduced, and the silicon content on the anode side has increased, increasing the volumetric energy density by more than 20%. Moreover, the voltage of the power battery, drive, and charging technology on the Neue Klasse platform will be increased to 800 volts, and the energy delivery to fast DC charging stations will be optimized. At a current of up to 500 amperes, the charging capacity will significantly increase, and the charging time from 10% to 80% will be reduced by 30%.

At the same time, the BMW Group's Board of Directors for Procurement and Supplier Network said in October last year that currently, BMW has signed contracts with multiple partners for five battery assembly plants. The assembly plants for BMW Group's sixth-generation high-voltage batteries are being built in Debrecen, Hungary; Woodruff near Spartanburg, USA; San Luis Potosi, Mexico; and Shenyang, China. In addition, BMW Group also plans to build a high-voltage battery assembly plant in Irlbach-Strasskirchen, a town downstream of Bavaria, Germany, to supply the whole vehicle factories in Munich, Dingolfing, and Regensburg. Among them, the Hungarian factory will be the first to launch the NEUE KLASSE model in 2025, and the Munich factory in Germany will launch it in 2026. Just last week, on May 3rd, BMW Group announced that its sixth-generation battery assembly plant in San Luis Potosi, Mexico, has started construction and will start supporting the production of an SUV model of NEUE KLASSE in 2027.

BMW’s global sixth-generation high-voltage battery assembly plant distribution

Construction begins on BMW's sixth-generation battery assembly plant in San Luis Potosi, Mexico

2024-11-08

2024-10-23

2024-10-22

2024-10-15

2024-10-14

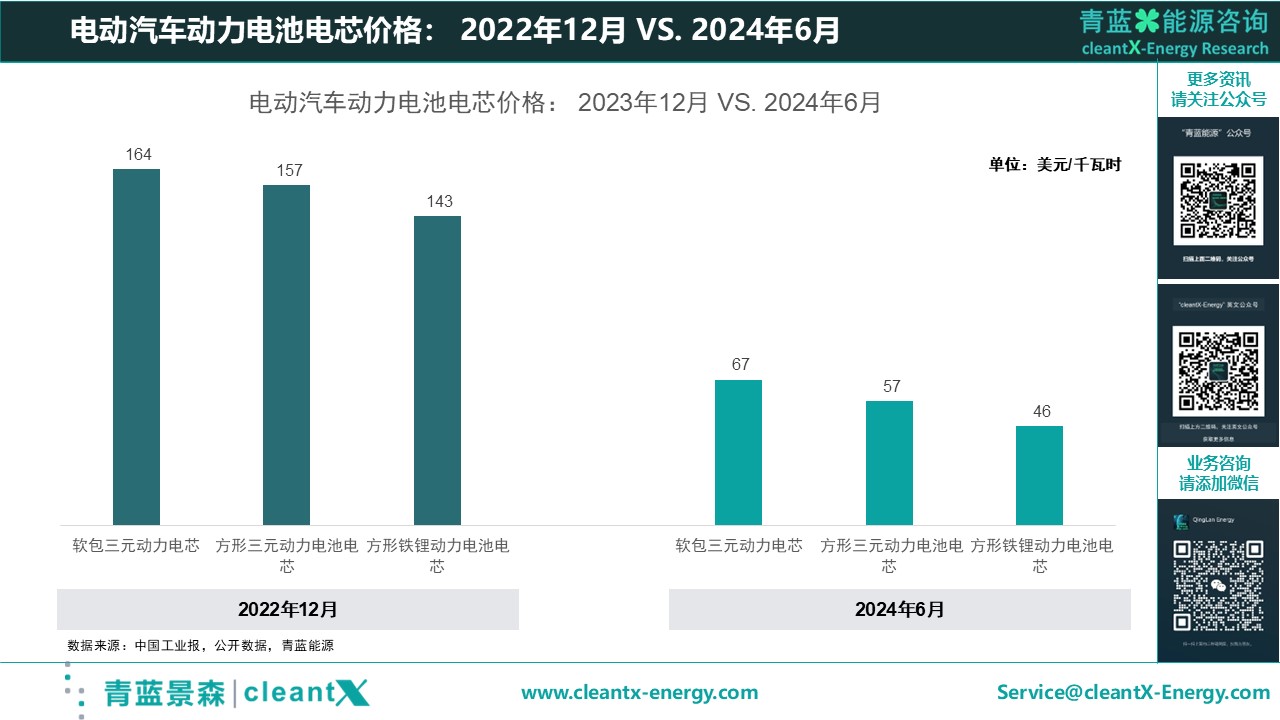

Lithium-ion Battery | EV Battery Cost Down 90% in 15 Years

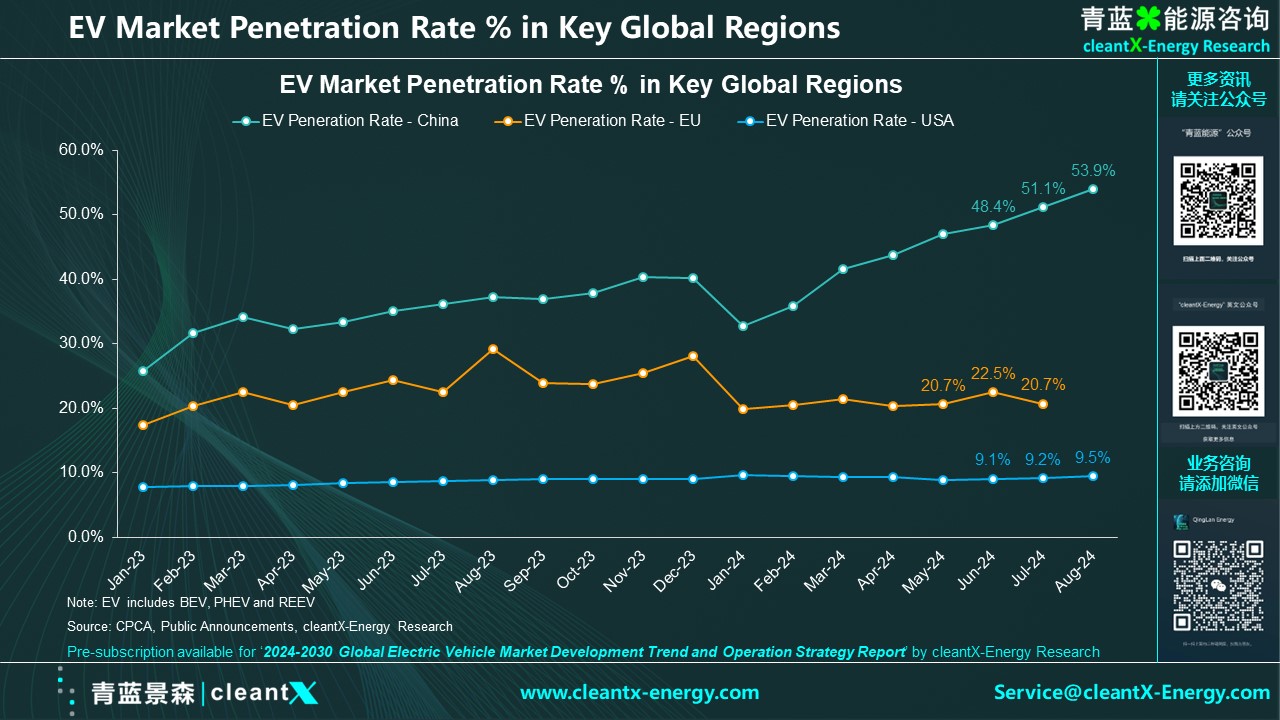

Electric Vehicle | China's EV Sales Keep Growing in August, with Market Penetration up to 53.9%

Lithium-ion Battery | Having IRA Tax Credits, The US Battery Production Cost to be Lower than China?

Electric Vehicle | Volkswagen Group's BEV Deliveries in Q3 Slide 10% Year-on-Year to 189,400 Units, but Up in China...

Electric Vehicle | China EV Sales up to 878,000 units in July 2024, with a retail penetration rate of 51.1%...

Electric Vehicle | Global EV Sales Record High in September

Electric Vehicle | EU sold 160,400 BEV and PHEV in July 2024, down 12.0% year-on-year; but HEV Sales Surge...

Electric Vehicle | EU Disclosed Duty on Chinese Electric Vehicles with Slightly Down