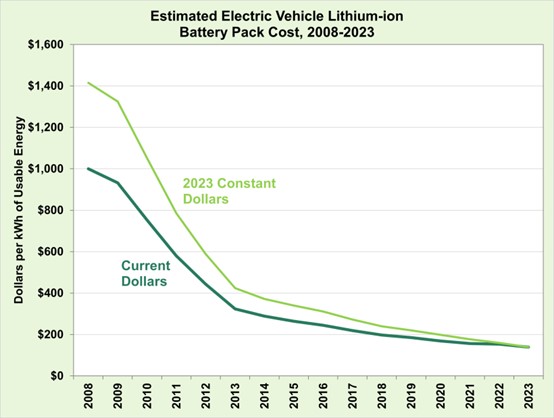

The U.S. Department of Energy (DOE) recently estimated that in the past 15 years, the average price of lithium-ion battery packs for light-duty electric vehicles has decreased by 90%.

According to the Vehicle Technologies Office (VTO) of the U.S. Department of Energy, which announced on August 5th, the cost of electric vehicle lithium-ion battery packs has dropped by 90% over the 15-year period from 2008 to 2023, from $1,415 per kilowatt-hour in 2008 to $139 per kilowatt-hour in 2023. The main drivers for the decrease in battery costs are improvements in battery technology and chemical composition, innovations in manufacturing processes, and a significant increase in production volume. The decline in the prices of battery minerals and materials is also one of the main factors driving the reduction in battery costs.

U.S. DOE: Cost Estimation of Electric Vehicle Lithium-Ion Battery Packs from 2008 to 2023

Looking at the cost curve, the decline from 2009 to 2013 was quite steep, and after 2013, it became more gentle. From 2010 to 2019, the price of lithium-ion battery packs dropped from $1,100 per kilowatt-hour to $156 per kilowatt-hour, a decrease of 87%. Just within the one-year period from 2018 to 2019, the cost reduction reached 13%.

BNEF predicted at the end of 2019 that by 2024, the price of battery packs would break the mark line of $100 per kilowatt-hour and continue to decline, with an expected price of $61 per kilowatt-hour by 2030.

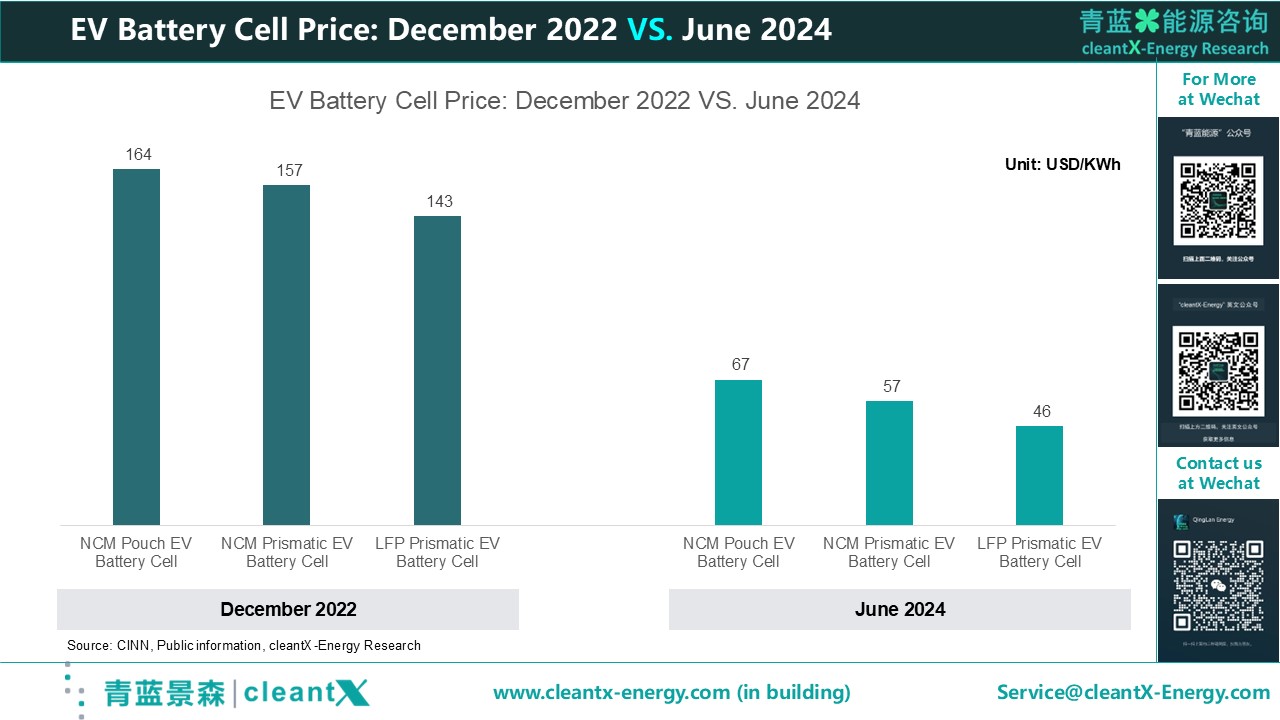

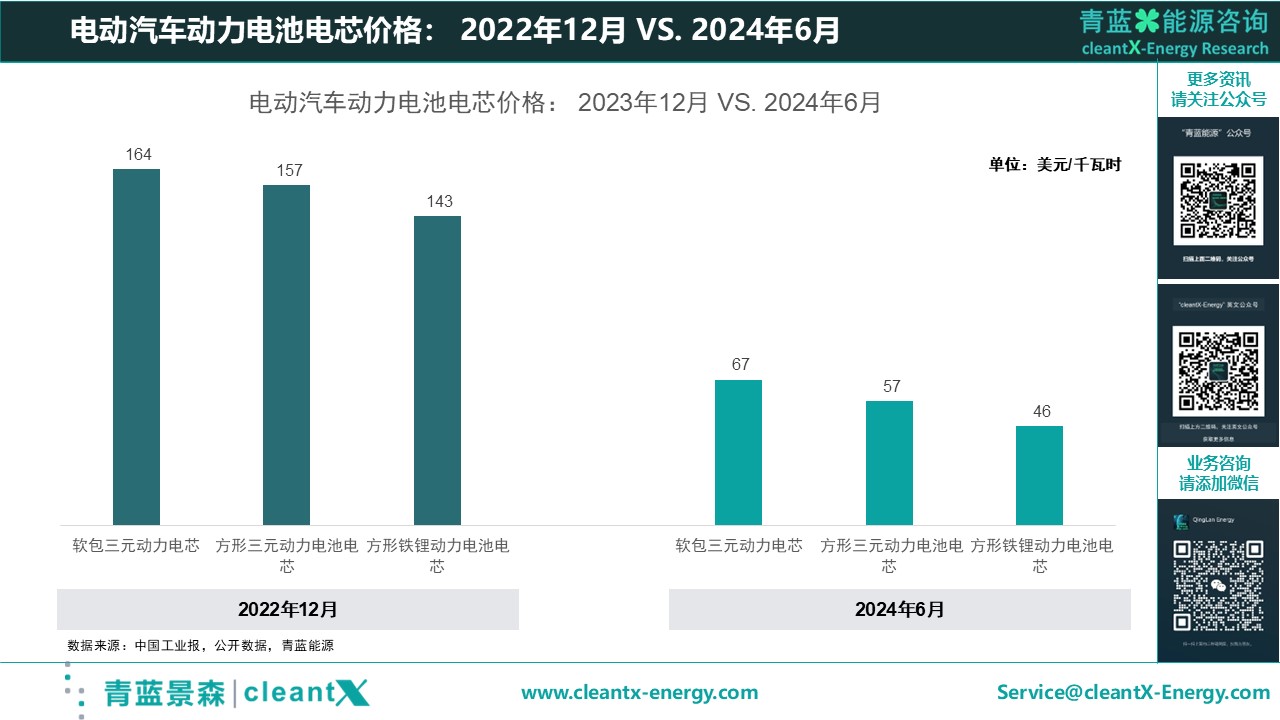

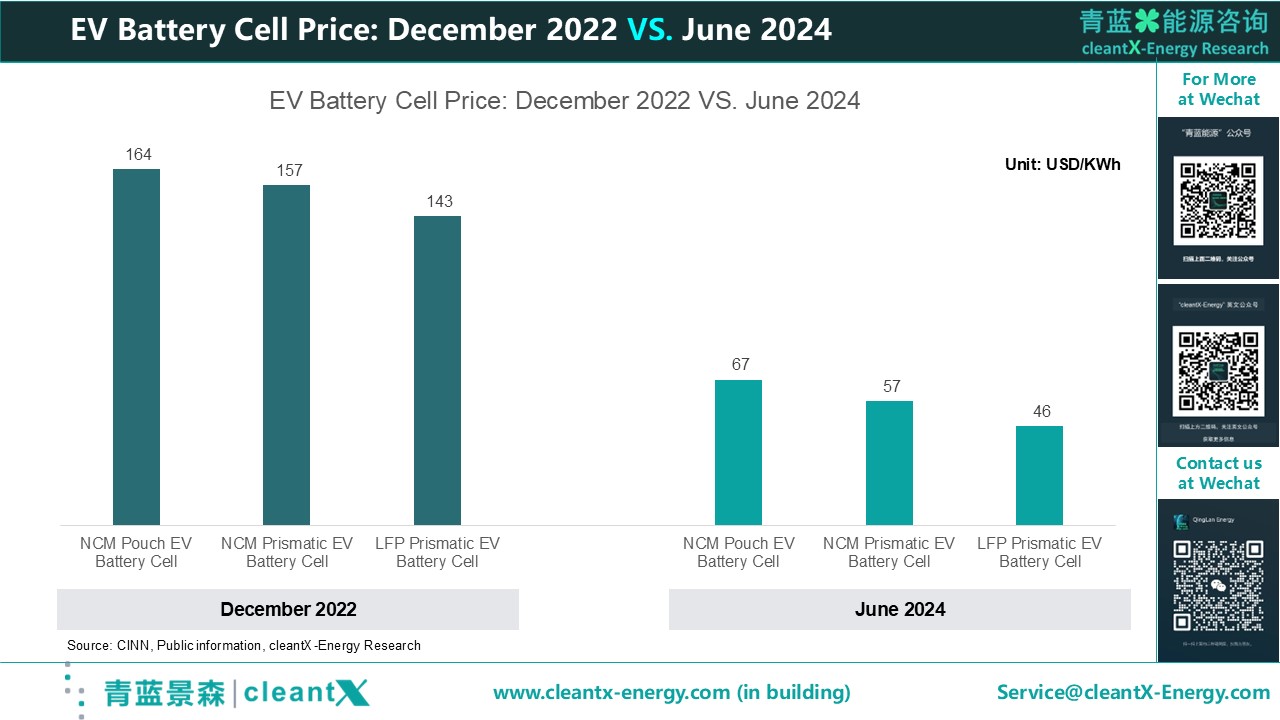

In the domestic market of China, according to recent statistics from the China Industrial News, from December 2022 to June 2024, in a period of nearly a year and a half, the price of pouch nickel-manganese-cobalt EV battery cells has dropped from 1,150 yuan per kilowatt-hour (about $164 per kilowatt-hour) to 470 yuan per kilowatt-hour ($67 per kilowatt-hour); the price of prismatic nickel-manganese-cobalt EV battery cells has dropped from 1,100 yuan per kilowatt-hour ($157 per kilowatt-hour) to 400 yuan per kilowatt-hour ($57 per kilowatt-hour); the price of prismatic iron-phosphate power battery cells has dropped from 1,000 yuan per kilowatt-hour ($143 per kilowatt-hour) to 320 yuan per kilowatt-hour ($46 per kilowatt-hour), with reductions of 59%, 64%, and 68% respectively. The current average price of power battery cells is only $57 per kilowatt-hour, which is already close to the cost level predicted by BNEF for the year 2030.

Given that the recent price of battery-grade lithium carbonate has already fallen below 80,000 yuan per ton, the cost of lithium-ion batteries is expected to decrease further, which will also drive down the cost of battery packs.

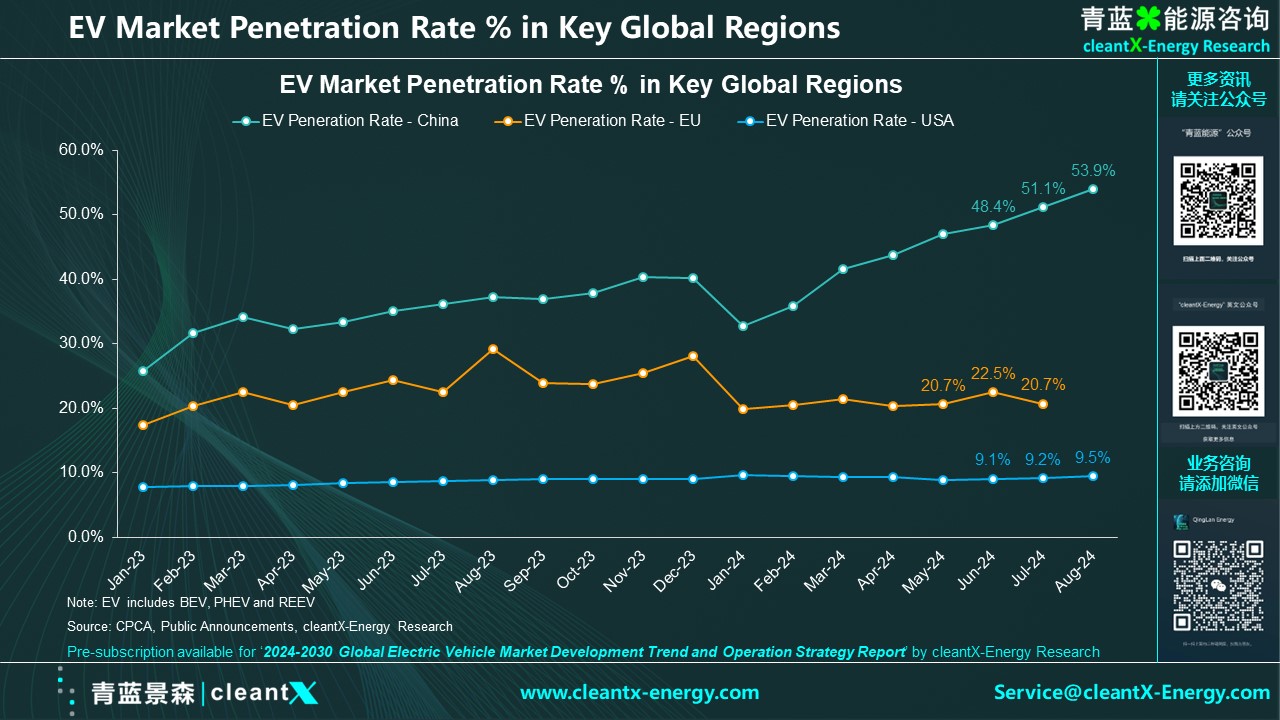

In China, due to the advantage of having a mature and complete power battery industry chain, the speed of cost reduction of Chinese power batteries will also be much faster than that of the United States. Currently, the prices of some electric vehicles have already equaled or even fallen below those of internal combustion engine vehicles, which will be more conducive to the popularization of electric vehicles. However, due to the lag in the development of the EV battery field in the United States, it will still take a period of transition to achieve parity between electric vehicles and internal combustion engine vehicles through the cost reduction of EV batteries. Goldman Sachs earlier this year predicted that the cost reduction between 2023 and 2025 would be equivalent to a 40% decrease, and according to its analysts, the reduction in battery costs may enable part of markets in the United States to achieve parity with internal combustion engine vehicles as early as next year.